Coverage

Coatings can be applied in a flood, or overall complete coverage, or in specific spots. Flood Coating is used mainly to give the finished piece an overall gloss, satin or neutral matte finish, while Spot Coatings or Spot Varnishes are used to make one specific area stand out.

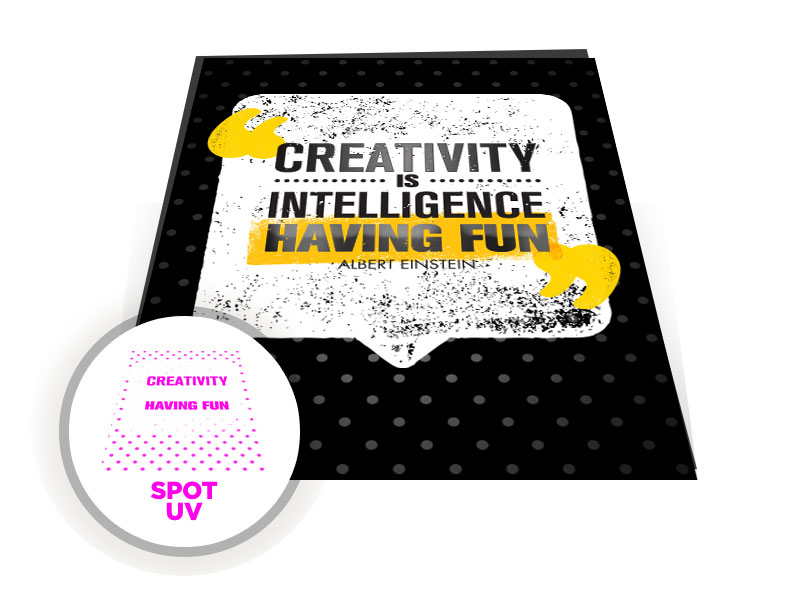

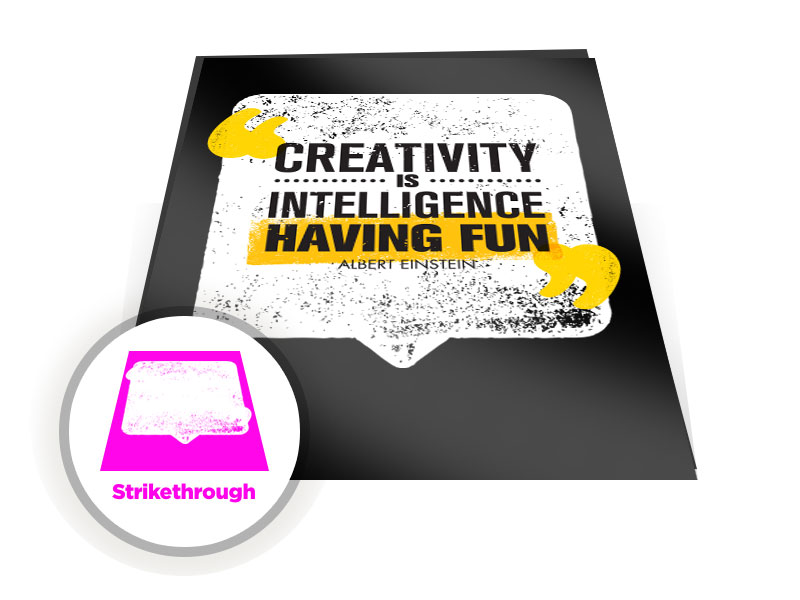

Spot Coatings

Spot Coatings cover only specific areas of a piece, such as logos, calls to action or photographs, but not other parts of the piece. This allows for a unique look that can make a printed piece pop. The process can be done in various ways, utilizing different processes at varying costs, however the effect is impressive and makes a piece feel more expensive.

Reverse varnishing on the offset press utilizes a process called Drip-Off Varnish or Strikethrough Coating where a dull finish is used for the non-gloss part and then the gloss is applied, only adhering to the unfinished areas. Spot Varnish can be done on the offset press as well as some digital machines utilizing a different process.

Traditional Spot UV is made of a material which does not yellow with age like Spot Varnish can over time. Depending on the application method and design, Spot UV can be thicker than Varnish creating raised areas, unique textures, ghosted images, and highlighting content.

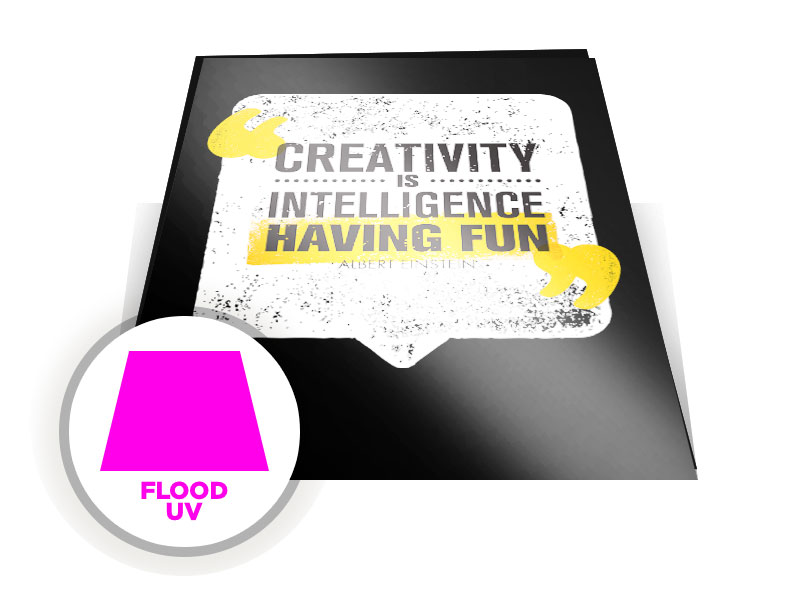

Flood Coating

Flood coating is the process of completely covering the face of a piece with a sealant. These coatings can come in different thicknesses, textures, and finishes.

Laminating

Laminates are a completely different process that seals the piece in between two sheets of heated plastic, creating a boundary for moisture which helps increase the life of pieces that will be handled repeatedly.

Coating Types

Varnish

Varnish is similar to a clear ink and technically is not a coating at all. It is applied during the printing process to coat a piece with a thin layer of protection or to make a certain area stand out. Varnish was the industry standard for ages, but technological improvements of both coating mediums and the ways in which they are applied have changed the world of coatings.

Aqueous

Aqueous is the most popular coating in use today. Aqueous coating is superior to Varnish in that it is shinier and smoother without the yellowing that can happen to Varnish over time. The water based coating is the choice for longer lasting pieces or those which have large amounts of white space. Aqueous is applied as a flood and not used in spot applications though as it is not as precise as Spot Varnish or Spot UV.

UV Coating

UV coating is similar to a plastic coating that protects pieces from wear and tear, and to a limited extent bleaching and moisture. The liquid coating is then cured by an ultraviolet light in a process called polymerization which hardens the finish.

Finish Types

Raised UV

Raised UV is a spot coating that is layered to give a 3D effect to logos or other design elements. The effect is similar to embossed pieces, but the UV plastic is built up over the print, as opposed to pressing a design into the paper.

Matte & Dull Finishes

A print coating does not need to be glossy. In fact, many pieces that are attributed to a glossy stock paper are actually coated to prevent wear and tear, ghosted images or other issues that can come up in the printing or delivery process.

Glossy & Super Gloss

High Gloss finishes are used in applications such as photographs, four color fliers, stickers or other pieces that benefit from the extra coverage. There are various ways to accomplish a Glossy or High Gloss finish, but the finished effect is usually visually similar.

Soft Touch Laminate & Coating

Not always an actual laminate, Soft Touch is a popular finish that fools the tactile senses into believing the piece is physically softer than it is, giving the piece a much more elegant feel.

Textured

Textured Finishes are a unique way to add depth and interest to a piece. The textured layer can be applied in spots, patterns or in a blanket to give the finished piece a custom appearance and feel.

Pearlescent, Sparkle & Glitter

Coatings aren’t necessarily just clear. Many different processes from specialty papers to actual coatings with Glitter or Pearlescent effects create a fantastic effect for specific pieces such as gift cards while essentially being a fraud deterrent.

Food Safe

The FDA (Food and Drug Administration) regulates what can come in contact with food, pharmaceuticals, etc. at any point in their production, processing, distribution or final packaging. FDA Approved inks and coatings are used to create labeling, packaging, inserts, or any other printed materials that might come into indirect contact with food or medicine.

Specialty

Specialty Coatings can be used to add a specific finish to your final piece. Scented coatings can add various smells to make your piece stand out by engaging with the end user in a completely new way. Glow-in-the-dark effects can reveal hidden elements in your piece or give it a new life once the lights go out. Hidden UV effects can be used with UV flashlights to reveal hidden areas as well. Chalkboard finishes create a reusable surface for chalk sure to create a conversation piece. Scratch-off tickets, or hidden code areas can be used to hide sensitive information or create a game out of your printed piece.

Turn the Volume UP

on your marketing with our expanded and

EXCLUSIVE 3D UV Finishing Services!

Your printed products tell a story every time someone sees, touches and holds your marketing materials. Sundance wants to make sure you are leaving a lasting impression and promoting your brand with the latest print technology. We are excited to announce our most recent purchase of MGI Jet Varnish 3D UV Machine. This equipment offers a unique way to literally turn the volume UP on your next project. Add a new level of dimension with our spot, raised or 3D sculpted UV to create a visual and tactile experience for your prospects and customers.

Request a sample kit and discuss how you can turn the volume up on your next project.

Request A Sample Kit Call Now Find Out More About Coatings Get A Quote Now